How-To Use An Industrial Saw: Step-By-Step Guide

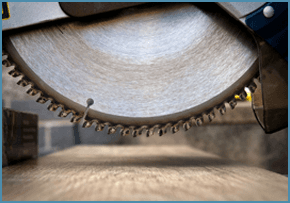

Industrial saws are essential tools in various manufacturing sectors, designed to provide precision and efficiency in cutting a wide range of materials. These powerful machines play a crucial role in industries such as woodworking, metalworking, and construction, allowing for the creation of intricate designs and components. With advancements in technology, modern industrial saws come equipped with innovative features that enhance their performance, safety, and ease of use, making them indispensable in high-volume production environments.

In this article, we will explore the different types of industrial saws available on the market, including band saws, circular saws, and table saws, along with their specific applications. We will also discuss key factors to consider when selecting an industrial saw for your operations, such as blade types, cutting capacity, and power requirements. Whether you are a seasoned professional or a newcomer to the industry, understanding these tools can significantly impact the efficiency and quality of your production processes.

Types of Industrial Saws

Among the various types of industrial saws, band saws are renowned for their versatility in cutting intricate shapes and large materials, making them ideal for both metalworking and woodworking applications. Circular saws, on the other hand, are typically used for straight cuts and are highly effective in high-speed cutting tasks, while table saws offer robust support and accuracy for larger workpieces. Each of these saws has unique attributes that cater to specific cutting needs, which is vital in achieving the desired outcomes in manufacturing processes. For those contemplating a purchase, understanding costs associated with these saws can be enlightening; you can learn more about pricing structures at https://nerdbot.com/2025/06/12/what-does-an-industrial-saw-cost/.

Factors to Consider

When selecting an industrial saw, several critical factors must be considered to ensure optimal performance. Blade types play a significant role, as different materials require specific blades for effective cutting. Additionally, evaluating the cutting capacity and power requirements of the saw is crucial to match it with the intended workload and material thickness. Safety features should also be a priority, as they protect operators during high-speed cutting operations. By weighing these factors, businesses can make informed decisions that enhance productivity and ensure the longevity of their equipment.

In conclusion, understanding the various types of industrial saws and the essential factors for their selection is vital for any manufacturing operation aiming for efficiency and precision. Band saws, circular saws, and table saws each offer unique advantages that cater to different cutting requirements across industries. By carefully evaluating blade types, cutting capacities, and safety features, businesses can invest in the appropriate equipment that not only meets their specific needs but also enhances overall productivity. As technology continues to advance, staying informed about the latest innovations in industrial saws can further optimize production processes, ultimately driving success and competitiveness in the fast-paced world of manufacturing.